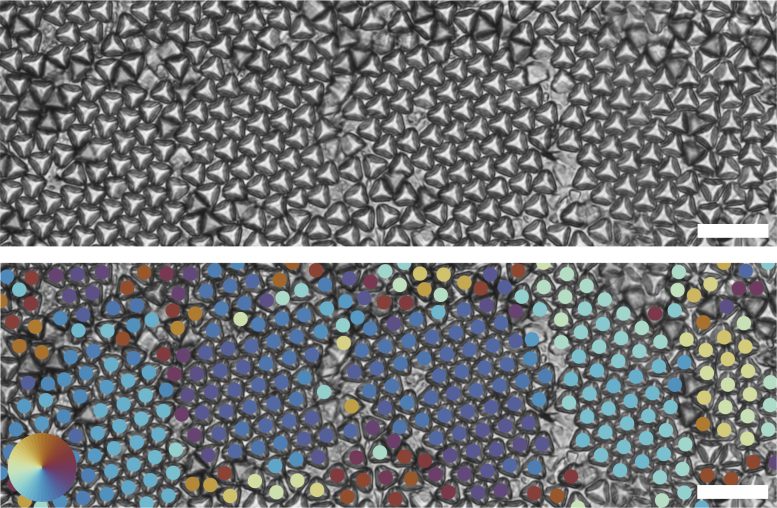

Optical images of truncated tetrahedrons forming multiple hexagonal grains (top). Bond order analysis shows different hexagonal grains through different colors (bottom). Neighboring tetrahedrons that have the same color indicate that they have the same grain orientation. Scale bar is 20 um. Credit: David Doan & John Kulikowski

Stanford material engineers have utilized 3D printing to create tens of thousands of hard-to-manufacture nanoparticles, that are expected to lead to the development of new materials capable of instantly altering their form.

In nanomaterials, shape is destiny. That is, the geometry of the particle in the material defines the physical characteristics of the resulting material.

“A crystal made of nano-ball bearings will arrange themselves differently than a crystal made of nano-dice and these arrangements will produce very different physical properties,” said Wendy Gu, an assistant professor of mechanical engineering at Stanford University, introducing her latest paper which appears in the journal Nature Communications. “We’ve used a 3D nanoprinting technique to produce one of the most promising shapes known – Archimedean truncated tetrahedrons. They are micron-scale tetrahedrons with the tips lopped off.”

In the paper, Gu and her co-authors describe how they nanoprinted tens of thousands of these challenging nanoparticles, stirred them into a solution, and then watched as they self-assembled into various promising crystal structures. More critically, these materials can shift between states in minutes simply by rearranging the particles into new geometric patterns.

This ability to change “phases,” as materials engineers refer to the shapeshifting quality, is similar to the atomic rearrangement that turns iron into tempered steel, or in materials that allow computers to store terabytes of valuable data in digital form.

“If we can learn to control these phase shifts in materials made of these Archimedean truncated tetrahedrons it could lead in many promising engineering directions,” she said.

Elusive prey

Archimedean truncated tetrahedrons (ATTs) have long been theorized to be among the most desirable of geometries for producing materials that can easily change phase, but until recently were challenging to fabricate – predicted in computer simulations yet difficult to reproduce in the real world.

Gu is quick to point out that her team is not the first to produce nanoscale Archimedean truncated tetrahedrons in quantity, but they are among the first, if not the first, to use 3D nanoprinting to do it.

“With 3D nanoprinting, we can make almost any shape we want. We can control the particle shape very carefully,” Gu explained. “This particular shape has been predicted by simulations to form very interesting structures. When you can pack them together in various ways they produce valuable physical properties.”

ATTs form at least two highly desirable geometric structures. The first is a hexagonal pattern in which the tetrahedrons rest flat on the substrate with their truncated tips pointing upward like a nanoscale mountain range. The second is perhaps even more promising, Gu said. It is a crystalline quasi-diamond structure in which the tetrahedrons alternate in upward- and downward-facing orientations, like eggs resting in an egg carton. The diamond arrangement is considered a “Holy Grail” in the photonics community and could lead in many new and interesting scientific directions.

Most importantly, however, when properly engineered, future materials made of 3D printed particles can be rearranged rapidly, switching easily back and forth between phases with the application of a magnetic field, electric current, heat, or other engineering method.

Gu said she can imagine coatings for solar panels that change throughout the day to maximize energy efficiency, new-age hydrophobic films for airplane wings and windows that mean they never fog or ice up, or new types of computer memory. The list goes on and on.

“Right now, we’re working on making these particles magnetic to control how they behave,” Gu said of her latest research already underway using Archimedean truncated tetrahedron nanoparticles in new ways. “The possibilities are only beginning to be explored.”

Reference: “Direct observation of phase transitions in truncated tetrahedral microparticles under quasi-2D confinement” by David Doan, John Kulikowski and X. Wendy Gu, 25 March 2024, Nature Communications.

DOI: 10.1038/s41467-024-46230-x

This work was funded by the National Science Foundation, a Stanford Graduate Fellowship. DD, JK, the Hellman Foundation, and the National Science Foundation. Part of this work was performed at the Stanford Nano Shared Facilities, which is supported by the National Science Foundation, and at the Stanford Cell Sciences Imaging Facility.