Glutenin, a wheat protein, shows promise for lab-grown meat production by supporting the cultivation of muscle and fat layers that mimic real meat’s texture and composition, offering a sustainable alternative to traditional meat as the global population increases.

As the global population grows, lab-grown meat, which consists of animal muscle and fat cells cultivated in lab settings, presents a promising solution to meet the rising demand for protein. Additionally, affordable plant proteins could serve as a foundation for these cell cultures. Recent findings published in ACS Biomaterials Science & Engineering demonstrate that the non-allergenic wheat protein glutenin successfully grew striated muscle layers and flat fat layers, which could be combined to produce meat-like textures.

Development of Plant-based Scaffolds for Cultured Meat

Cultured cells need a base or scaffold to adhere to produce lab-grown meat. Plant proteins are appealing candidates for the scaffolds because they are edible, abundant, and inexpensive. Previous researchers showed that a plant-based film made of glutenin was a successful base to cultivate cow skeletal muscle cells.

But for this technique to produce a promising meat-like alternative, the muscle cells need to form aligned fibers, similar to the texture in real tissues. Additionally, fat needs to be included in the 3D structure to replicate the composition of traditional meat products. To take advantage of using glutenin, a protein in gluten that people with celiac disease or a gluten sensitivity don’t typically react to, Ya Yao, John Yuen, Jr., Chunmei Li, David Kaplan, and colleagues wanted to develop plant-based films with it to grow textured muscle cells and fatty layers.

Experimental Results and Future Directions

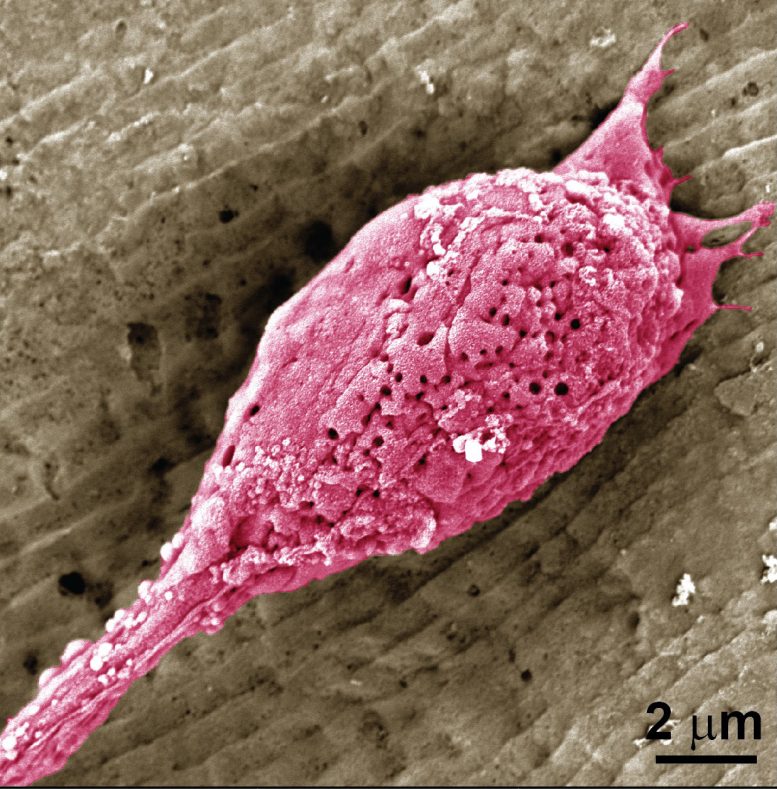

The researchers isolated glutenin from wheat gluten and formed flat and ridge-patterned films. Then they deposited mouse cells that develop into skeletal muscle onto the protein bases and incubated the cell-covered films for two weeks. Cells grew and proliferated on both flat and ridged films. As expected, compared to cells grown on control films made of gelatin, the performance of the glutenin-based films was inferior but sufficient. The researchers say further work needs to be done to improve how cells attach to the plant-based film to get closer to the growth on the animal-derived biomaterial. During the second week of the culture, the cells on the patterned film formed long parallel bundles, recreating the fiber structure of animal muscles.

By putting ridges in a plant protein base, cultured muscle cells grew in a pattern that mimics the alignment of muscle fibers in animals. Credit: Adapted from ACS Biomaterials Science & Engineering 2024, DOI: 10.1021/acsbiomaterials.3c01500

In another test, mouse cells that produce fat tissues were deposited onto flat glutenin films. During the incubation period, as cells proliferated and differentiated, they produced visible lipid and collagen deposits.

The cultured meat and fat layers attached to the edible glutenin films could be stacked to form a 3D meat-like alternative protein. Because the glutenin material base supported the growth of both textured animal muscle and fat layers, the researchers say it could be used in an approach for more realistic cultivated meat products.

Reference: “Cultivated Meat from Aligned Muscle Layers and Adipose Layers Formed from Glutenin Films” by Ya Yao, John S. K. Yuen, Jr., Ryan Sylvia, Colin Fennelly, Luca Cera, Kevin Lin Zhang, Chunmei Li and David L. Kaplan, 16 January 2024, ACS Biomaterials Science & Engineering.

DOI: 10.1021/acsbiomaterials.3c01500

The authors acknowledge funding from MilliporeSigma and the U.S. Department of Agriculture. Some authors are employees of MilliporeSigma, Inc.